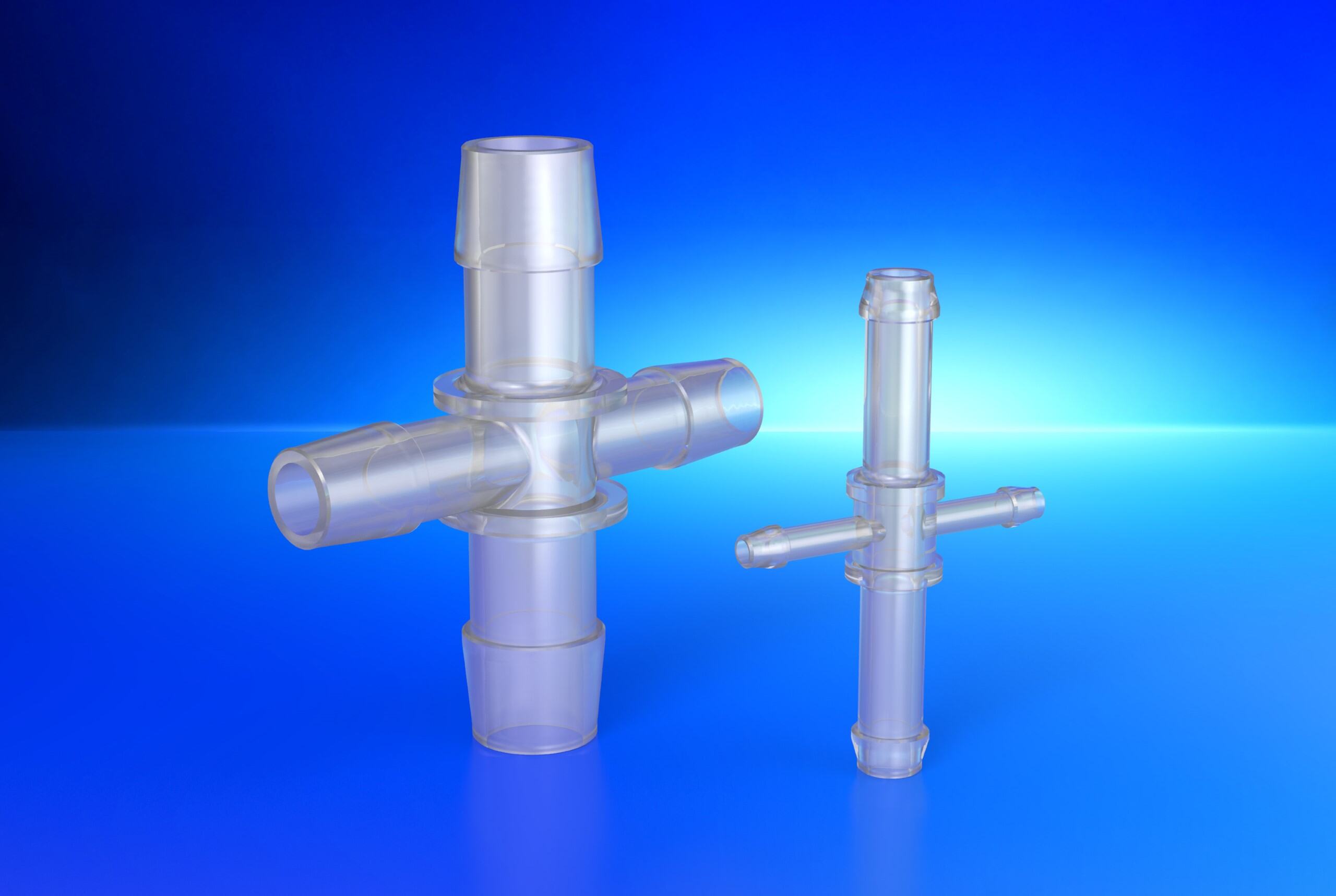

Single-Use Concentric Reducing Crosses

- Precision-fit Tri-Clamp® connections

- Zero animal-derived materials

- Adherence to FDA protocols

- USP Class VI tested

- Minimal contamination risks

- Effortless system integration

- Complete lot traceability

- Gamma irradiated for sterility

- Smooth internal transitions

- Optimized process synergy

The polypropylene Reducing Cross from Contour BioSolutions features four connection points in an X-shaped configuration, enabling multi-directional flow transitions between different pipe sizes. These crosses integrate seamlessly with our range of elbows, tees, caps and other essential parts designed for efficient yet flexible construction of single-use technology systems.

Bioprocessing and pharmaceutical applications adhere to a non-negotiable standard for sterility, driven by stringent guidelines established by regulatory bodies and the integral drive for the highest product quality and safety. All system components fabricated by Contour BioSolutions rely solely on robust, FDA-compliant materials with the option of gamma irradiation to ensure thorough sterilization. This meticulous approach dramatically reduces contamination risks and instills unwavering confidence among our customer base that relies on our reducing cross for critical bioprocessing operations.

Our Reducing Cross represents the intersection of function and efficiency, engineered to withstand the rigors and dynamics of contemporary facilities for single-use or limited-run production. Each Reducing Cross features standard TC flange compatibility meeting ASME-BPE specifications, providing leak-proof, resilient interfacing with other components. This creates a seamless, robust transition within your SUT while protecting cells and sensitive products through elimination of sharp internal angles.

Reducing Crosses from Contour BioSolutions offer our customers:

Leveraging only industry-approved materials, our Reducing Crosses are fabricated using FDA and USP Class VI-certified compounds. Whether it is polypropylene, Kynar® (PVDF), or platinum-cured silicone, the choice hinges on compatibility with the chemical and processing environment.

Our Reducing Crosses span a spectrum of standard sizes, designed to seamlessly integrate with any of our caps, elbows, tees and other parts to configure your ideal processing system. Custom sizes are available upon request.

Every Reducing Cross we manufacture is lot traceable, which is part of our commitment to quality, transparency and accountability.

All parts we fabricate offer the option for gamma irradiation, to lend the thorough sterility required for hygienic and secure bioprocessing and pharmaceutical applications.

Each part is free from animal-derived ingredients to supply uncompromised purity of bioprocessing tasks and to align with your company’s ethical standards.

Count on Contour BioSolutions’ Reducing Crosses as dependable components for process line applications within the biopharmaceutical industry in filling machines, mixing containers and vessels, fermenters, bioreactors, filtration systems and more.

Spanning our diverse offerings, from adaptors to elbows, tees and more, each product resonates with our uncompromising quality ethos. These adaptors supply adaptability to fit effortlessly into systems from compact benchtop operations to more expansive floor models. Single-use technology components from Contour BioSolutions quickly and nimbly create limitless configurations for unique applications. SUTs help limit the risks of traditional stainless steel equipment for a contamination-free environment.