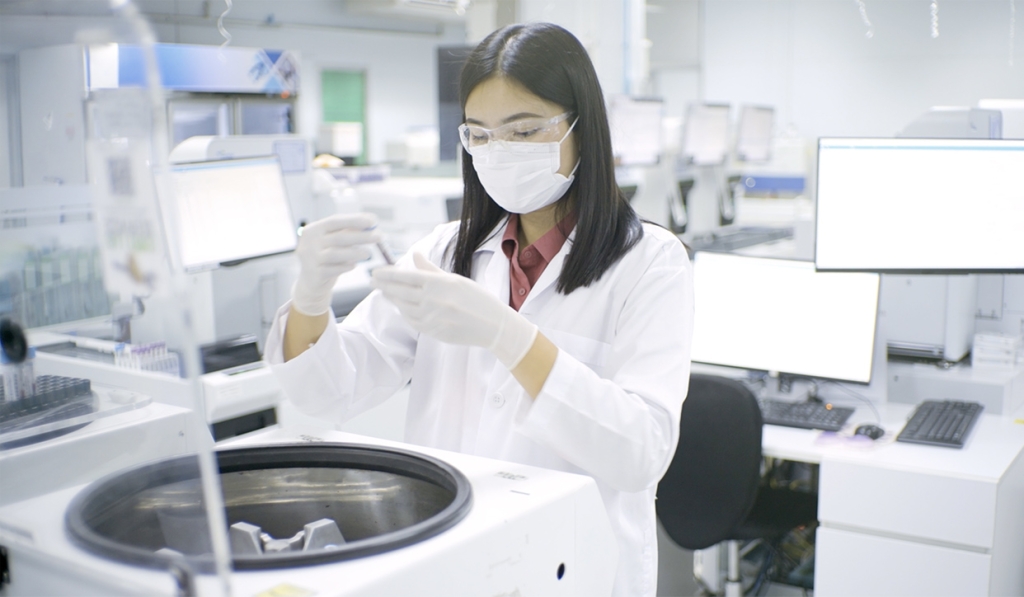

Single-Use Assemblies for Pharmaceutical Processing

The pharmaceutical sector is undergoing a transformative shift alongside the rise of single-use bioprocessing technologies. SUTs for bioprocessing continue to boast an impressive market trajectory. Valued at $11.0 billion in 2021, the global single-use bioprocessing market is predicted to post a robust CAGR (Compound Annual Growth Rate) of more than 18% from 2022 through 2030, according to various market research reports.

The increasing use of SUTs is linked to the growth of new therapeutic modalities such as cell and gene therapy or antibody-drug conjugates. These new modalities might require smaller batches, more rapid shifts in production, or, in the case of cell and gene therapies, exhibit greater sensitivity and require a higher degree of sterility than traditional stainless-steel equipment.

Implementing single-use technology (SUTs) within bioprocessing operations qualifies as a more sustainable option than legacy processes.

Single-Use Assemblies Preferred Over Stainless Steel

Bioprocessing companies are increasingly turning to single-use systems as a preferred processing choice due to their multiple advantages compared to stainless-steel setups and semi-disposable systems. Contrary to the ecological footprint of some disposable components, implementing single-use technology (SUTs) within bioprocessing operations qualifies as a more sustainable option than legacy processes.

Stainless-steel reusable setups require enormous amounts of chemicals and water and a corresponding energy expenditure to perform clean-in-place (CIP) sanitary processes—necessary steps when sterilizing reusable equipment to prevent cross-contamination, clear bacterial growth and preserve product quality and integrity.

Diminish Dependence on CIP Processes

SUTs eliminate the need for this intense dependency on CIP or COP (Clean Out of Place) procedures and the extensive outlay of associated precious resources. In addition, SUTs are economical, operationally efficient and minimize cross-contamination risks, with each product flow path designed for one-time or limited use.

These systems employ disposable technologies for developing and manufacturing vital pharmaceutical products, including vaccines, monoclonal antibodies and personalized medicines. The adoption of SUTs spans both drug development and biopharmaceutical manufacturing operations. The result is a transformation of upstream and downstream manufacturing processes to make them quicker and more flexible while also more straightforward and cost-effective.

Several factors are driving this surging market for SUTs:

While challenges implementing SUTs remain, including the stringent regulations governing the use of disposable systems within the pharmaceutical segment, Contour BioSolutions has created a product portfolio of components that meets and exceeds these industry standards to supply the flexibility and sterility required.

Contour BioSolutions offers sterile parts needed to configure a system that can meet the unique requirements for small to mid-sized batches or production runs. Our parts supply leak-free connections and offer the flexibility to design and cost-effectively create a serviceable and flexible processing system. Call Contour BioSolutions today for single-use technology that answers your operation’s needs.